As science and industrial production continue to advance, the measurement of viscosity in substances has become a crucial aspect of various processes. One of the most widely used tools for this purpose is the rotary digital viscometer, which allows for the accurate measurement of viscosity and flow behavior of polymer liquids.

The concept of rotary viscometry was pioneered by the Brookfield family in the United States, who introduced a rotational viscosity measurement method. This method relies on the unique relationship between shear and resistance generated between the rotating rotor and the fluid to obtain dynamic viscosity values. Over the years, this technology has evolved and improved, and today's rotary viscometers, like the brookfield viscometer series, offer exceptional performance and versatility.

Rotary digital viscometers come in different types, each tailored for specific applications:

Drum Viscometer: This type features a flat-bottomed cylinder with a coaxial cylinder in the center. The polymer liquid is placed in the slit formed between the two parallel surfaces. The cylinder is rotated by a stepless governor, and the viscosity of the liquid causes the cylinder to rotate until the torque balances with the spring force. The resulting angle of rotation provides information about shear force and shear rate at various positions in the annular seam.

Vertebral-plate Viscometer: Consisting of an upper cone and a lower disc, this viscometer has the cone and the circular plate on the same axis and both are rotatable. The polymer melt is placed in the slit formed by the cone and the circular plate at a specific angle. When the circular plate rotates, it drives the cone to rotate until a certain angle is reached, providing viscosity data.

Falling Ball Viscometer: Though less commonly used for measuring melt viscosity, this type is suitable for Newtonian fluids. It involves a ball falling through the liquid, and the maximum shear rate near the ball can be estimated. However, data processing can be challenging, and it is not ideal for comprehensive analysis of non-Newtonian fluids.

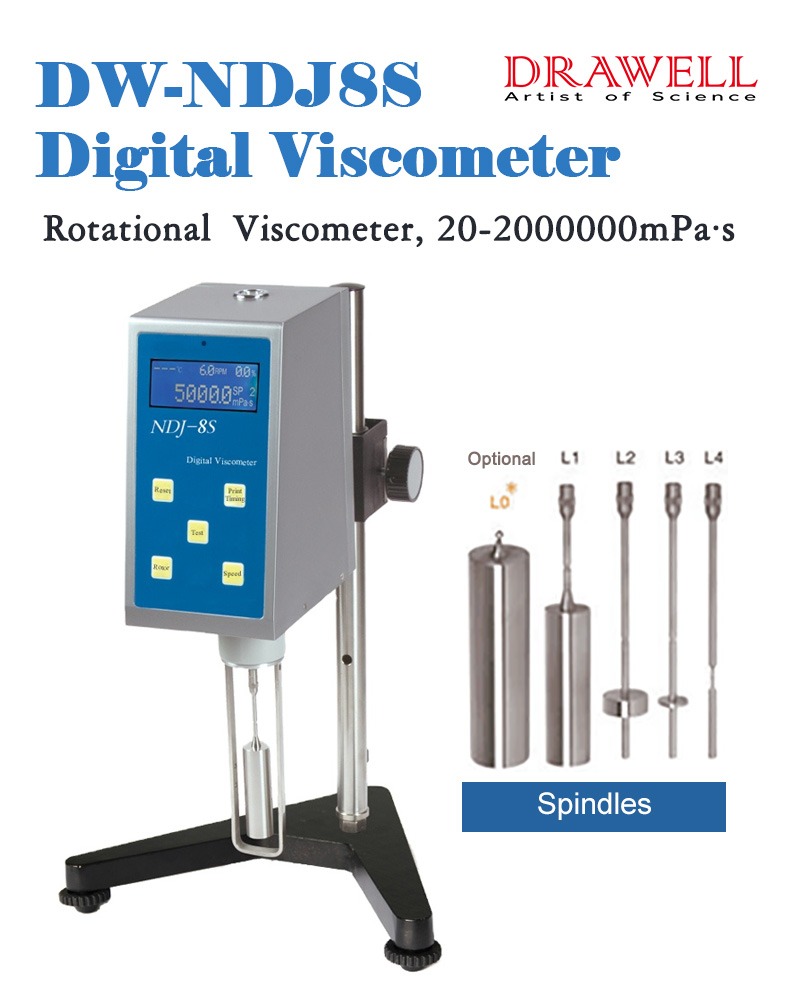

When selecting a rotary viscometer, the NDJ-8S type low viscosity viscometer is a popular choice with the following main parameters:

Measuring Range: 10 ~ 1×10^5 mPa.s

Rotor Specifications: 0, 1, 2, 3, 4, and No. 5 rotors (No. 0 rotor optional, for low viscosity down to 0.1 mPa.s)

Instrument Speed: 6 rpm, 12 rpm, 30 rpm, 60 rpm

Measurement Error: ±5% (Newtonian liquid)

Power Supply: 220V ± 10V; 50Hz

Net Weight: 1.5 Kg

When choosing the appropriate rotor and speed, one should estimate the viscosity range of the liquid to be tested and then refer to the range table. For instance, if the viscosity is around 3000mPa·s, a No. 2 rotor at 6 rpm or a No. 3 rotor at 30 rpm could be suitable.

If the viscosity cannot be estimated, a higher density should be assumed, and a range of rotors and speeds should be used, starting from small rotors and slow speeds for high-viscosity liquids and vice versa for low-viscosity ones.

To calculate the actual viscosity from the indicated viscosity on the dial, a specific coefficient from the coefficient table must be used. Additionally, if the frequency of the power supply is inaccurate, the NDJ-8S rotational viscometer can be corrected using a simple formula.

In conclusion, rotary digital viscometers offer invaluable insights into the viscosity into the viscosity and flow behavior of polymer liquids, playing a vital role in modern industrial processes. Proper selection and utilization of these instruments can significantly enhance the efficiency and quality of various applications in the field of polymer production and beyond.